Non-Destructive Testing

Non-Destructive Examination (NDE)

Non-Destructive Testing (NDT)

Sometimes known as Non-Destructive Examination (NDE), Non-Destructive Testing applies techniques such as ultrasound and thermal imaging to assess the integrity of materials and locate defects and faults.

Non-destructive Testing employs techniques to test discontinuities and other flaws in a material, component or structure without in any way harming that material, component or structure. Prior to an NDT survey YSG will discuss with you the most appropriate method of testing for your vessels specific condition.

Ultrasound

Ultrasound testing is a non-destructive method used to measure the thickness of shell plating and structure on metal vessels (steel and aluminum). The readings are used to estimate the metal loss/waste due to corrosion and to ensure the remaining metal is sufficient for the vessel to maintain it's structural integrity.

Readings can be taken internally with the vessel afloat, but for a full survey the vessel should be on hard standing with clear access to the underwater surfaces. The hull needs to be cleaned of marine growth and any poorly adhered paint system. Staging and ladders should be provided for larger vessels. At YSG the Ultrasound testing device we use is a CYGNUS 4 and employs multiple echo system to read thickness with +/- 0.1 mm accuracy without the removal of the paint system. The Cygnus 4 is checked multiple times for accuracy using a calibration block. The location of the readings are recorded in the survey report so at any time thicknesses can be rechecked in known areas.

Moisture Readings

The object of taking moisture meter readings is to determine whether moisture is being absorbed and retained by the GRP laminate. The meters provide a quick, accurate and non-destructive check for retained moisture. Persistently high moisture readings taken over a period of weeks may indicate an Osmotic condition. Moisture meters can also be used to help identify water absorption into cored hull or deck laminate.

Yacht Survey Group uses electronic moisture meters by Tramex and Protimeter. Specifically, the Tramex Skipper, which is primarily designed for glass fiber boat hulls, but can also be used on timber to identify leaks in wooden decks.

Before the survey, the hulls should be jet washed and cleaned of all marine growth. It is also important that bilges are dry and well ventilated as moisture meters can sometimes read through the hull. Moisture meters do not work on carbon fibre. Finally, YSG provide a report detailing the findings along with any recommendations.

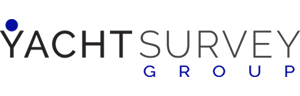

Thermal Imaging

This kind of examination is effective for some types of defect inspections, and functions by detecting levels of and variations in temperature in a hull or structure with a Thermal Imaging camera; at YSG we use a Flir E5 camera.

Thermal imaging can sometimes help to identify hull defects including moisture ingress into core materials of GRP hull and decks. It can also be useful to identify problems with machinery and electrical systems.

The vessel or a specific area of the vessel may need to be heated for effective examination and this will be discussed with you prior to the NDT survey.

Dye Penetrant Inspection

Dye Penetrant Inspection (DPI), also known as Liquid Penetrant Inspection (LPI), is a widely used, and time and cost efficient non-destructive method that detects surface-breaking discontinuities in non-porous materials such as steel, aluminum and GRP. The test area is cleaned, sprayed with a dye penetrant, a developer is then added and the final inspection is carried out visually.

Osmosis & Moisture Level Testing

Fiberglass hulls are subject to water absorption and over time this can affect the hull condition. Using a variety of moisture meters we can inspect a GRP hull with regard to moisture ingress in the laminate, or core material on composite yachts. Meters can read through most paint systems but the underwater surfaces should be cleaned of all marine growth and washed. Scrapings will usually be made to remove some small coupons of paint system to inspect the underlying gelcoat or epoxy barrier system. If blistering (Osmosis) is present recommendation will be given on appropriate courses of action that can be taken. YSG has written an article on the subject which can be found here….

Systems, Machinery & Propulsion

A machinery and systems survey is recommended following works undertaken to repair damage, or to test the systems on a newly built yacht. This survey will usually involve a sea trial. The scope of the survey very much depends on the systems onboard but would typically include running up and the operation of the following: Main engine(s), generators, steering and autopilot, bow/stern thrusters, stabilizers, winches, windlasses, air conditioning, bilge pumps, fresh water systems, grey/black water systems, refrigeration, heating, gas/ electric.

Safety Equipment

Safety equipment recommendations greatly depend on the intended use of the yacht. Our recommendations with generally follow MCA (Maritime Coastal Agency) requirements for small commercial yachts (up to 24m load line length). The recommendations vary according to the distance the yacht intends to sail from a port. .

We were able to interest you?

Our Approach

Our ultimate aim has always been to enable sailors and boat people to enjoy yacht ownership with peace of mind. Central to our vision is the client's interest. The ethics of a fair purchase are at the forefront of our minds, and safety is paramount. The bottom line of YSG is looking after the client's interest by accurately assessing the condition of the yacht. This gives the client reliable information about the yacht allowing them to make it safe and also to ensure it is a worthwhile investment.

About YSG

Marine surveyors based in Bodrum,Turkey and operating Internationally.

Joe Rowles: British; qualified, Internationally accredited independent marine surveyor authorised to carry out MCA coding inspections for vessels under 24m load line length through the following; certifying authorities: IIMS, YDSA and RYA (Royal Yachting Association). Background in Engineering.

Ali Dincer: Turkish; Independent certified Marine Surveyor by IIMS (International Institute of Marine Surveyors) Diploma as a Yacht & Small Craft Surveyor. RYA inspector and accredited expert witness for Turkish Courts.